Description

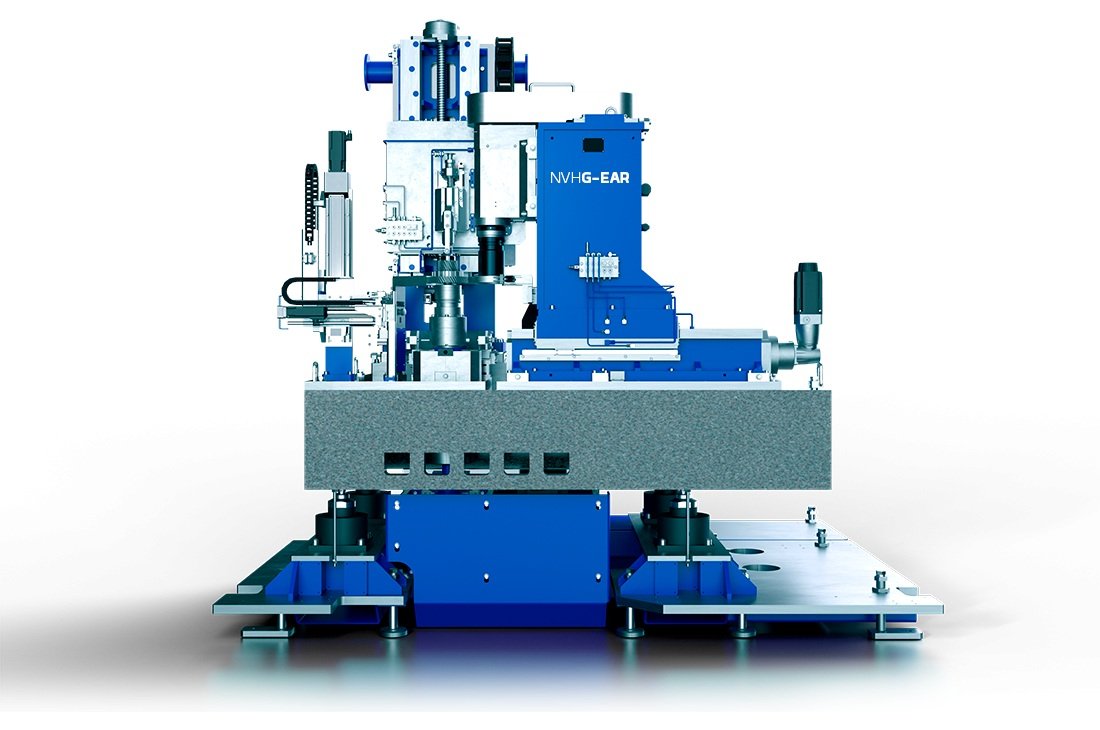

Marposs NVH G-EAR tester, that works on the Single Flank testing principle of one master gear meshing with the component under inspection, is able to detect macro-geometry (nicks, runout etc.) and micro-geometry (gear mesh excitation, ghost orders) defects that are responsible of gear whine and noise phenomena.

The ability of achieving high values of torque and rotational speed and the possibility to adjust them at will during testing, is one of the major benefits of the application, which allows testing the gears at operating conditions almost comparable to those found in the final e-Drive.

A robust granite base frame to become non-sensitive to external interferences and disturbances and a highly configurable software make Marposs NVH gear tester at the forefront of technology in the sector, capable of correlating data with the End Of Line test rig.

The output parameter is the angular acceleration (rad/s2) evaluated instantaneously and in the long run.

The signal of the sensor is elaborated to obtain the FFT spectrum to show the amplitude of the frequencies of vibrations.

The spectrum normally shows a range of frequencies related to the gear meshing frequencies and relevant sidebands, whose amplitude is usually related to the transmitted load. Unexpected high amplitude are related to ripples.

Reviews

There are no reviews yet.