Description

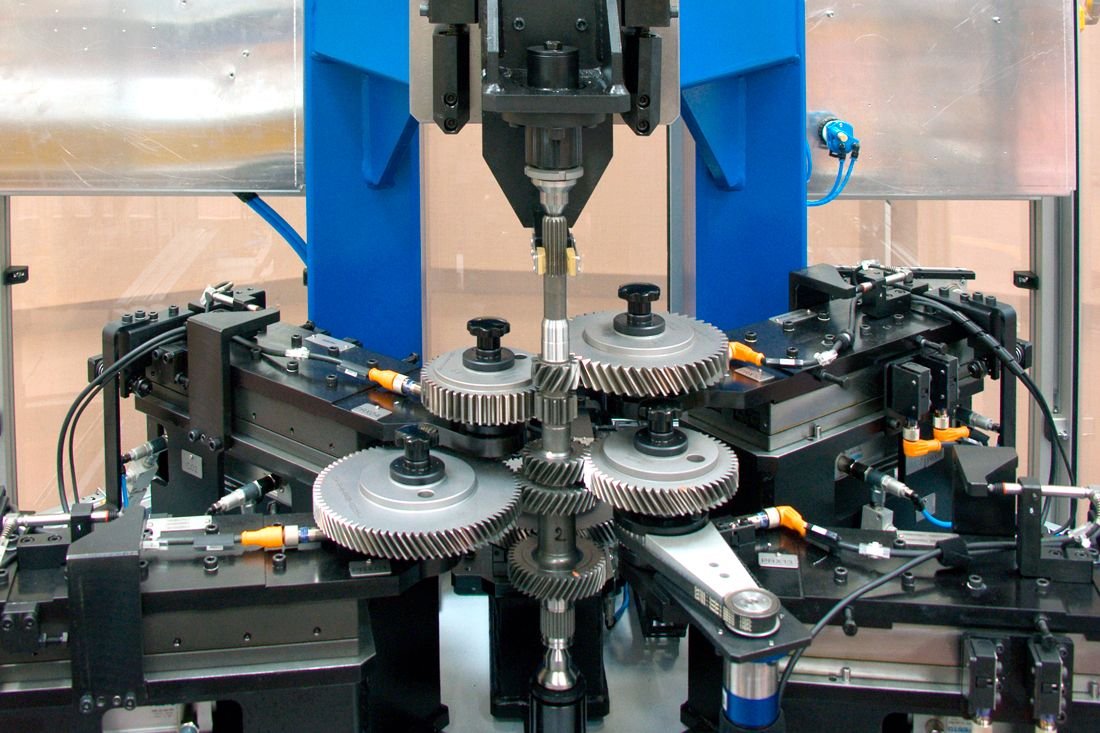

The M62 gear inspection line includes manual gauging instruments as well as automatic machines to match all the inspection requirements of the production process of a gear.

According to the specific operation along the process, Marposs can offer solutions to inspect:

- Dimensional parameters: OBD, Pitch Diameter, Root Diameter, OBR, ID, Distances, Parallelism and Perpendicularity between surfaces and shape errors

- Functional parameters: gear roller checks (Fi”, fi”, Fr”, Aa”, FTT, Nicks)

Depending on the gauge function, the measuring instrument is calibrated with artifacts (masters) that are of similar geometry to the production gears inspected, or full part like artifacts in the case of functional gauging.

Marposs can offer a complete series of masters manufactured in standard gauge steel (62-64 HRC) or high speed tool steel (HSS) and with surface treatment like TiN coating.

All master gears are provided with certification as per DIN 3961-3962 specifications.

All the M62 gauging systems can be connected to a wide range of Marposs innovative electronic interfaces and industrial computers. Through the dedicated Gear AddOn software, compatible with Microsoft Windows® and Marposs QuickSPC™, it is possible to perform accurate gear analysis with the support of Cartesian and Polar graphic elaborations.

Reviews

There are no reviews yet.