Description

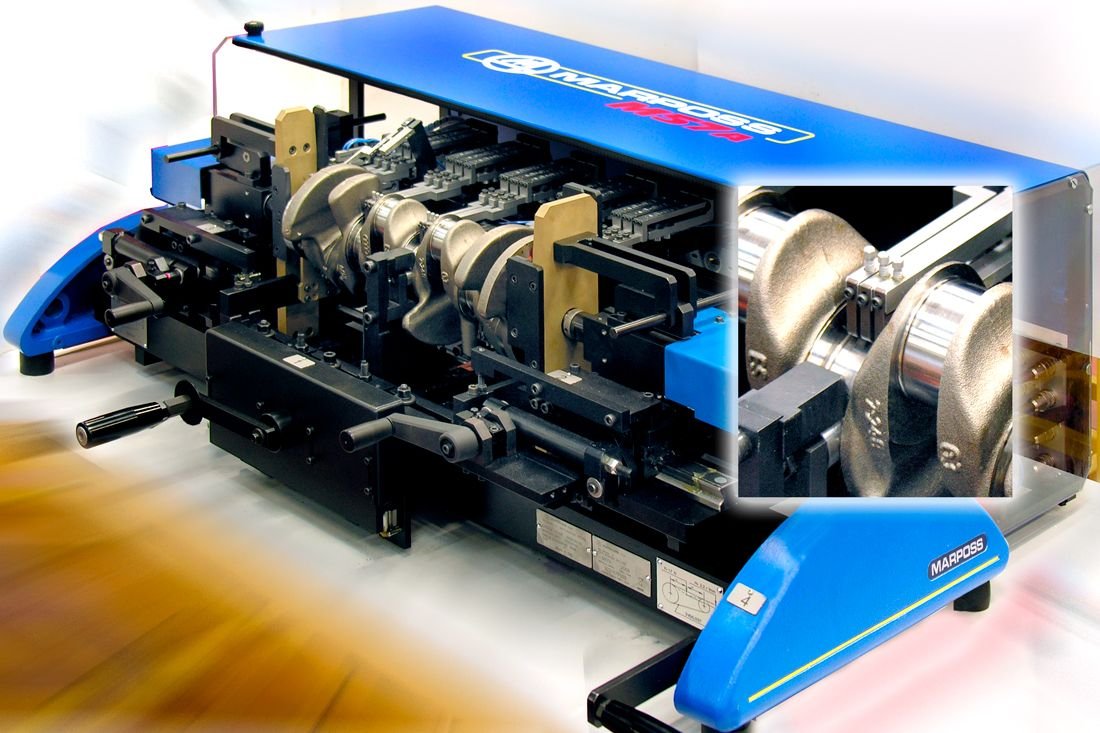

M57A is a manual or automatic loading gauge station that can be used to check the dimensional and geometric measurements of shafts such as:

- Crankshafts

- Camshafts

- Gear shafts

- Rotors

- Axle shafts

With this system, the checks can be performed in the final and inter-operational phases.

Guarantees comparable repeatability and accuracy of a metrological laboratory.

Perfectly able to check and certify the production of shafts directly in the workshop environment.

It can perform the following commonly requested inspections:

- Outside diameters

- Straightness and barrel shape of main bearings

- Stroke / Index

- Ovality

- Taper

- Concentricity

- TIR

- Distances

- Cam base circle / cam lift

- Perpendicular of shoulders

- Angular phase of bores / key way seats

M57A is supplied with:

- Adequately protected insulated gauge station that guarantees the stability of the measurement controls;

- Part reference system consisting of Vees or centres; possible options are, pre-Vees with passive dampers, motorized Vees, motorized automatic centers, and ambient temperature compensation.

- Precise and maintenance free slide moves the gauge station on the part.

Manual or automatic gauge station loading, orientation and operation.

The bench is connected to the Marposs E9066T industrial PC.

Reviews

There are no reviews yet.