Description

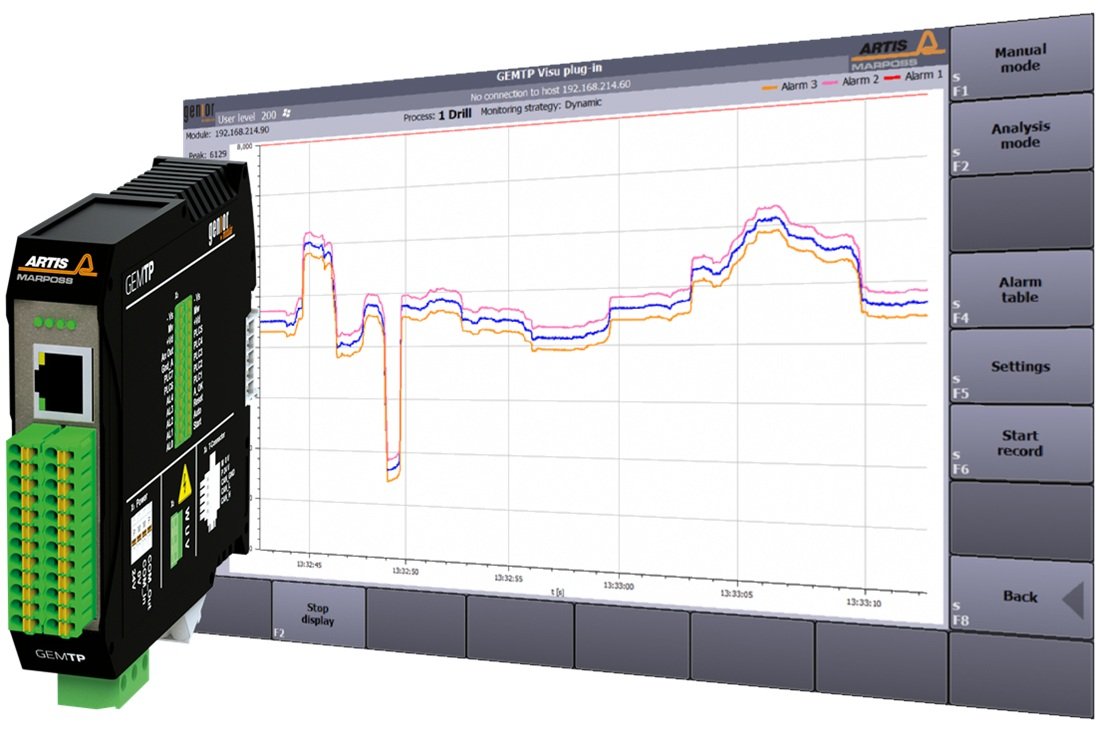

Placed in the electrical cabinet, GEMTP is a highly effective stand-alone module for identifying the tool status. Marposs Hall sensors CT-100 (100 A) or LA-205S (200 A) measure the true power values absorbed from the spindle during the machining process.

GEMTP provides 3 different monitoring strategies and it can handle up to 127 different cutting cycles with 4 types of limits (e.g. tool breakage/missing, overload and tool wear) for each cycle. All events trespassing pre-fixed limits are recorded in a log-file.

The compact GEMTP module is designed for easy installation and operation and can easily be installed in cabinets and housings of machines, robots or other performance-controlled devices. All necessary functions and interfaces are integrated in the module.

Thanks to its hardware I/O interface, GEMTP is independent of the NC type and can be triggered by any PLC, allowing a discrete connection to the module connections.

GEMTP can be used in stand-alone mode with operating software running in Windows (Win 7/10) based controls. In case of non-Windows controls the operating software can be installed on Marposs 7”/10” terminal units or on any PC (Win 7/10).

As a part of the GENIOR MODULAR product family, GEMTP can be easily connected to the GEMCPU and become a part of the high-end GENIOR MODULAR system. The acquired measurement signal is then additionally used by the GEMCPU unit for automatic monitoring strategies. In parallel the module can still be operated in stand-alone mode.

Thus, Marposs offers an extremely flexible solution, which can be adapted to changing needs by adding any GENIOR modules (Operation with GENIOR MODULAR: Interface CAN bus).

Reviews

There are no reviews yet.