Description

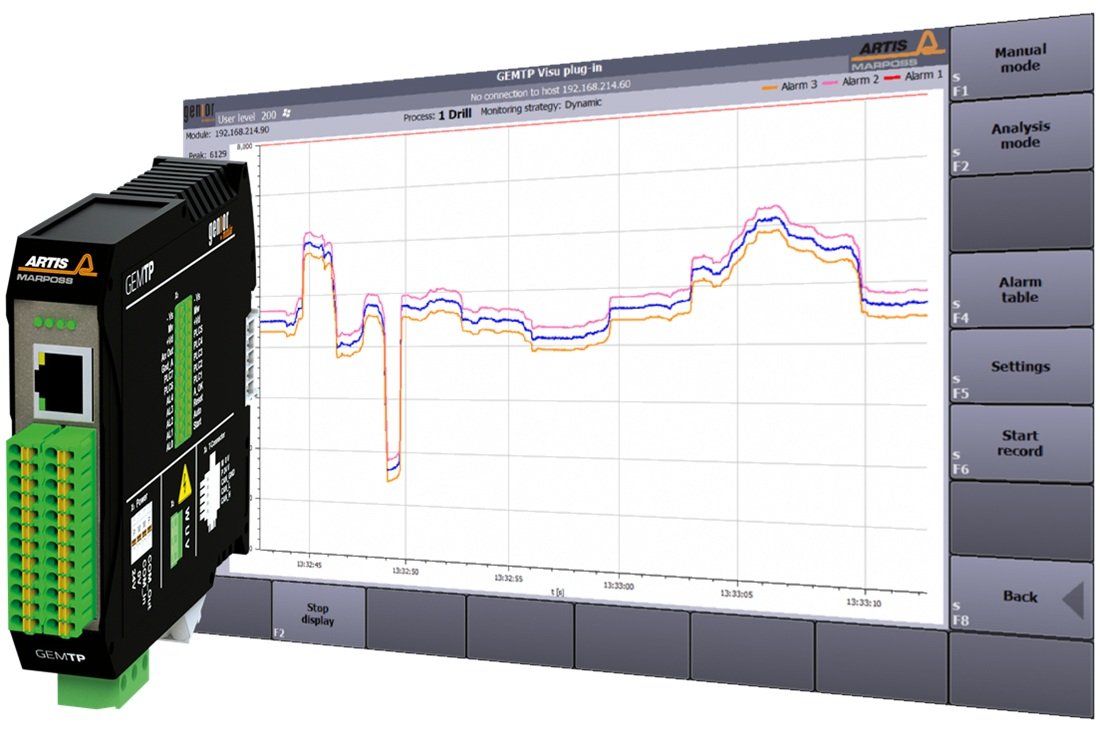

The modular system makes use of all relevant process signals and data from machine tools. It reacts in real-time after an event occurs. The system captures the measurement data digitally via fieldbus interface or via sensors and then evaluates the data based on multiple criteria and visualizes the processes in a transparent way. Trend or alarm reports support the users to optimize processes and allow to produce much more efficiently.

In addition to the described functions, data (BIG DATA) are collected and converted into information (SMART DATA) which can be stored locally or on network devices for further evaluations like analysis, trend curves, statistics and reports.

The option Adaptive Control adjusts the set feed rate of the cutting cycle, so that the effective force of the tool is as stable as possible. A reduction of cycle time can be the result of this feed rate optimization.

GEMCPU is also capable of detecting the wear of a brushing tool and thus automatically adjusting the feed axis.

The modularity of the system is one of the characteristic features needed to adapt the monitoring system to dedicated systems and machines. It is easy to integrate additional function modules, for example GEMTP, GEMGP and GEMVM.

The MultiView process visualization gives an overview about all parallel monitoring processes. Additionally, zooming, back tracing and filtering of different cycles is possible as well. Via Plug-ins (APPs) additional and/or customized functions can be activated, like csv-export, trend curves or statistics.

The option „FINGERPRINT“ (condition monitoring) shows variations in vibration and torque. An alarm will be given when these changes are still marginal and reach set limits to enable status-oriented maintenance.

Reviews

There are no reviews yet.