Description

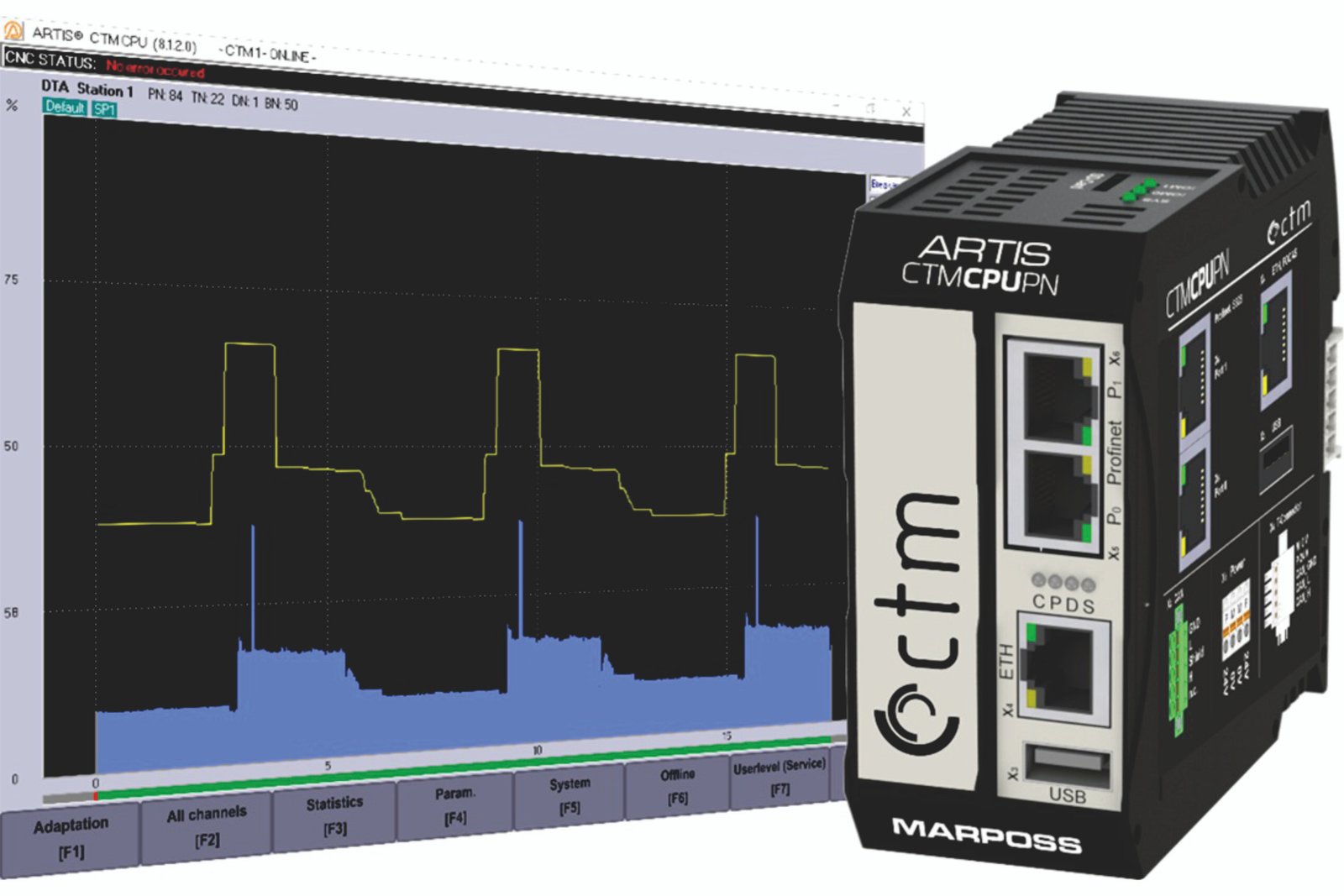

The CTMCPU system is a powerful monitoring system. By using dedicated strategies and interfaces CTM also provides process control (friction stir welding, brushing, riveting, deburring, assembling, etc.).

A Digital Torque Adapter (DTA) option uses the machine feed force- and torque data (e.g. SIEMENS compile cycle, FANUC FOCAS etc.) from the machine controls. Up to 8 drives can be monitored in parallel.

To meet the requirements and technical specifications, CTMCPU can be adapted to almost any production scenario with different dedicated monitoring strategies and analysis software:

- Gear hobbing: focus on safeguarding the expensive milling cutter and on increasing the milling cutter tool life

- Fluid: focus on checking the proper coolant flow rate.

- Statistics: focus on process analysis in order to find and eliminate reasons of a malfunction

- Adaptive Control: focus on continuously adapting the processing speed to the condition of material, tools and machines.

- With the process documentation option recording events, data collection and data transfer to different (network) devices can be realized. The function prepares the data for C-THRU4.0.

Integration

CTMCPU offers utmost flexibility to the OEM. The many configuration options allow the integration into any given system architecture:

- CTMCPU with the Ethernet connection to IPC of the NC control

- CTMCPU with GEMBOX via VNC connection

- CTMCPU with external IPC independent of the NC control

Reviews

There are no reviews yet.