Description

There are three types of balancing heads:

- Flange (FT): installed on the grinding wheel, outside the spindle. They are usually used on simple and economical grinding machines, without the automatic grinding wheel change. They are very easy to install and therefore ideal for retrofitting and they can be fitted with an acoustic sensor to check the grinding process.

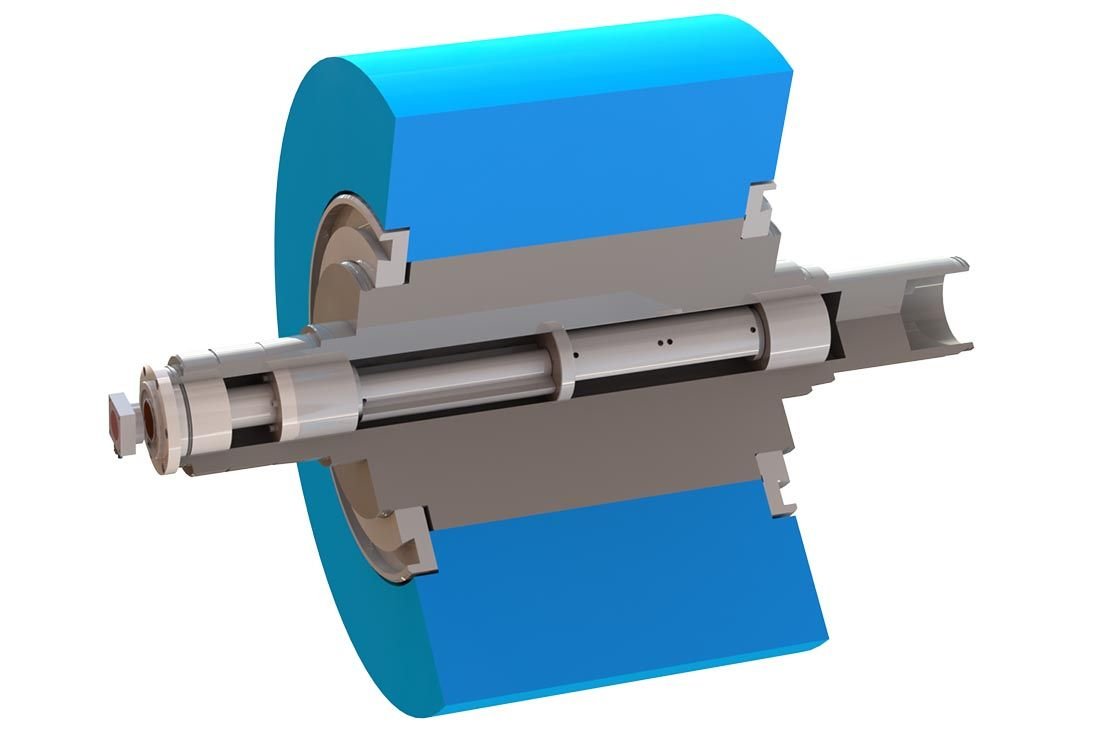

- Spindle(ST): built-in and they operate inside the spindle. They are usually used on top of the range grinding machines with front spindle, that operate at high and extremely high speeds, and therefore require an increased balance between the grinding wheel and spindle centre of gravity.

The range allows for a composition of diameters and lengths to achieve the balancing capacity. The balancing heads inside the spindle are fitted with a built-in acoustic sensor that allows maximum sensitivity and response time. Furthermore flange or expansion self-locking systems are available to lock them to the spindle. - Hydraulic (HT): installed on the grinding wheel support flange. They are usually used on grinding machines with automatic grinding wheel change and spindles that do not allow standard balancing heads to be used. In these types of heads the imbalance is compensated by injecting coolant, or oil in three or four balancing chambers that are integrated in the balancing container or directly in the grinding wheel flange. The balancing container is available in different shapes to meet the customer’s requirements. They are very easy to install, making them ideal for retrofitting on grinding machines that do not have an automatic balancing system.

The FT and ST balancing heads can be connected to the following systems:

BLÚ P1dWB P7WB DS5000 DS6000 DS7000

Reviews

There are no reviews yet.