Description

The monitoring systems based on acoustic technology, monitor the noise emitted when the grinding wheel touches the part or the dresser. The noise is generated during the cutting action and is transmitted through the grinding as ultrasound waves. As these waves pass through the various machine components, the frequency and amplitude change. By monitoring these waves any changes during the machining can be checked and therefore corrective actions can be implemented on the machine. The effectiveness of the sensors is dictated by their positioning, as close as possible to the machining area.

Monitoring with acoustic sensors is used to determine the contact between the grinding wheel and the part or the dresser, reducing the air gap time. The changes in the acoustic emissions can indicate changes in the force due to the cutting conditions of the grinding wheel and allow the cycle to be adapted, thus optimising the production process.

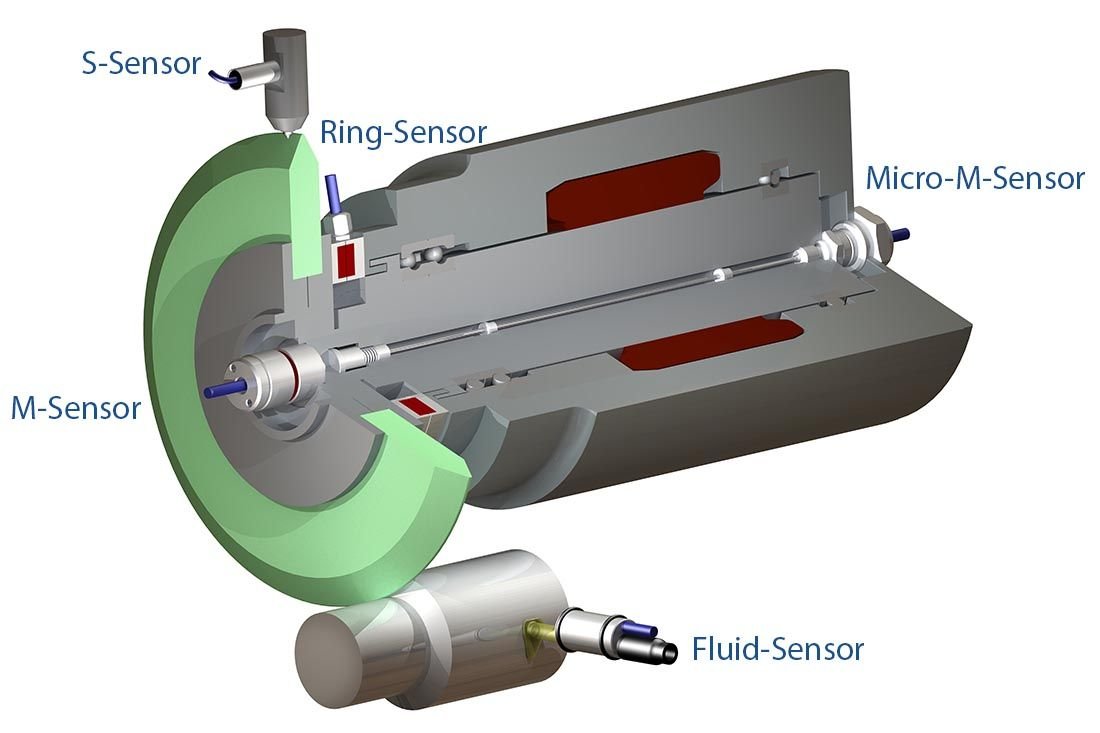

There are two series of acoustic sensors:

- Fixed acoustic sensors: the sensors consist of a single piece and the signal can be transmitted in air or through a liquid. Different dimensions are available to meet every application requirement.

- Contactless acoustic sensors: the sensors consist of a fixed part (stator) and a rotary part (rotor), but have different shapes and dimensions to meet every application requirement. The signal is transmitted without a direct contact between the rotor and stator.

The sensors can be connected to the following systems:

Reviews

There are no reviews yet.